Exploring How Fanless Computers Work: An In-Depth Look at Fanless Cooling

Have you ever wondered why some computers do not have a fan? Why computers used in factories are often fanless? What is the advantage of a fanless computer and how does a fanless computer work? In this discourse, we will explore how fanless computers operate without conventional cooling fans, the two principal types of cooling in computers: active and passive, and the industrial and commercial applications of fanless computers.

A fan is a common peripheral for heat-dispatching. However, fans require regular cleaning and are easy to gather dust, resulting in needing a lot of shutdown time for cleaning. Therefore, a fan is not an ideal cooling solution for a harsh environment such as mining or vehicle cabin.

To maintain steady operation in such an environment, fanless computers leverage heat sinks and convection cooling to manage thermal dissipation. This method allows for more efficient operation and a low failure rate, making it particularly beneficial in dusty or harsh environments which require such as vehicle cabins or harsh and in extreme environments where traditional cooling systems may falter.

How Does a Fanless Computer Work?

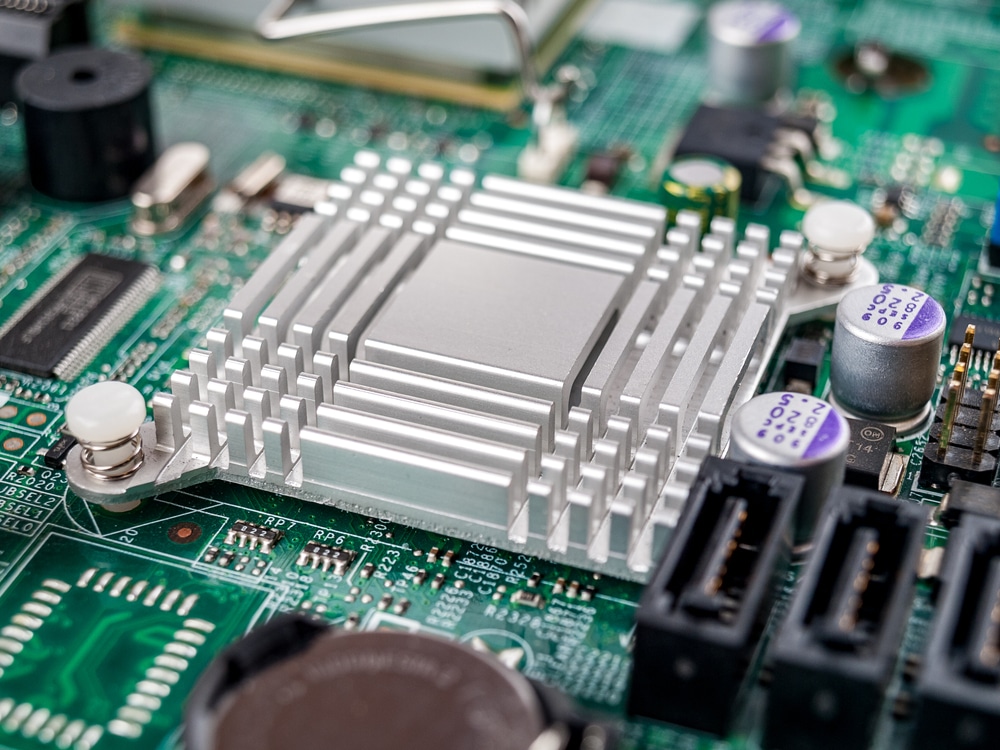

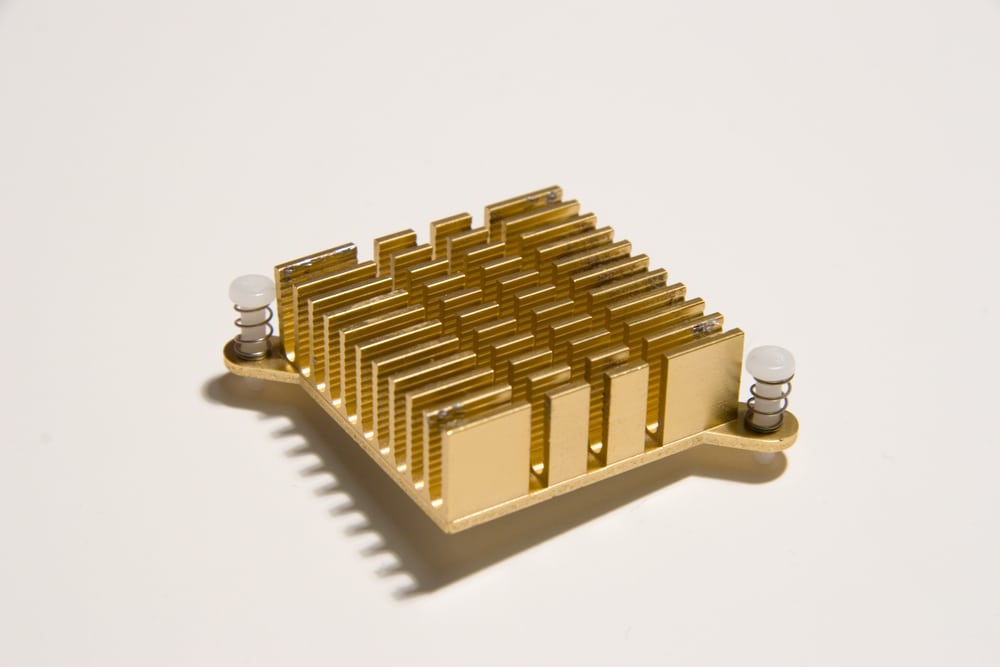

A fanless computer utilizes passive cooling techniques to dissipate heat, eliminating the need for a fan and reducing both failure rate and power consumption. The design of a fanless computer includes components such as heat sinks, heat pipes, thermal pad and grease, and cooling fins on the chassis.

The heat sink, typically made of an excellent thermal conductor such as copper or aluminum, attaches to heat-generating components like the processor (CPU) or graphics processing unit (GPU). By absorbing heat and spreading it across a larger surface area, the heat sink enhances effective cooling. Heat pipes, which contain a liquid that vaporizes and condenses in a cycle, transfer heat away from the source to the chassis or heat sink.

The most recognizable feature of a fanless computer perhaps is the mountain-like cooling fin on the chassis. The cooling fin acts as a large heat sink, absorbing and conducting heat from the internal components and radiating it into the surrounding environment. Additionally, cooling in strategically permits natural convection, allowing cooler air from the environment to enter the system, absorb heat, and then rise to exit the system while carrying the heat with it. This is how a fanless computer ensures effective heat transfer and dissipation through passive cooling. However, it may also require components that generate less heat or run at lower clock speeds to prevent overheating. Balancing between performance and heating is a huge challenge for fanless computer manufacturers,

Active vs. Passive Cooling in Computers

The following is a table to show active vs. passive cooling in computers:

|

Criteria |

Active Cooling |

Passive Cooling |

|

Definition |

Active cooling systems use energy to cool a component, usually with fans or liquid cooling systems. |

Passive cooling systems do not use any active mechanical or electrical components but instead heat sinks, pipes, or radiators to dissipate heat. |

|

Durability |

The mechanical components in active cooling systems can wear out over time and often need to be clean |

Passive cooling systems, having no moving parts, can last for the lifetime of the computer. |

|

Heat Management |

Active cooling systems can direct heat out of the system effectively. |

Passive cooling systems distribute heat within the system, often relying on case design for external dissipation. |

|

Noise |

Active cooling systems can generate noise due to mechanical components like fans. |

Passive cooling systems are silent as they do not use mechanical parts. |

|

Energy Consumption |

Active cooling systems consume additional energy as they need power to run. |

Passive cooling systems do not consume additional energy for operation; hence, they are energy efficient. |

|

Maintenance |

Active cooling systems often require regular maintenance, like cleaning fans or refilling coolant, to ensure optimal performance. |

Passive cooling systems require minimal maintenance as they have no moving parts. |

|

Complexity of Design |

Active cooling systems can be complex due to the need for additional components such as fans or pumps. |

Passive cooling systems are generally simpler, primarily involving materials that conduct heat away from components. |

|

Cooling Capacity |

Active cooling systems can achieve higher cooling capacities for higher performance and overclocking. |

Passive cooling systems can effectively cool components within their thermal limits and provide sufficient cooling for standard usage. |

|

Space Requirements |

Active cooling components like fans or liquid coolers may occupy more space in a computer case. |

Passive cooling systems like heat sinks are often more compact. They can be integrated into the design of the component itself. |

Critical Applications and Advantages of Fanless Computers

Industrial fanless computers find extensive use in various industries such as aerospace, medical equipment, military, vehicle, manufacturing, and retailing. This section delves into the advantages and applications of industrial fanless computers, highlighting their life-critical level.

What are the Applications of Fanless Computers?

- Aerospace (spaceship, rocket, aircraft): In the aerospace sector, fanless computers manage onboard avionic systems, data acquisition, navigation systems, and controlling payloads. These computers must comply with industry standards, be rugged, and resist extreme temperatures, vibration, and radiation.

- Medical Equipment: Medical equipment relies on fanless computers to process data in complex imaging devices like MRIs and CT scanners, control surgical robots, or manage patient information systems. In such applications, these computers must adhere to strict safety standards, be reliable, and produce low noise.

- Military-related (Tank, Launching System): Fanless computers are utilized in military applications for vehicle control systems, surveillance, targeting systems, and missile launching systems. They must comply with military electromagnetic/environmental compatibility standards, and resist shock, dust, and water.

- Vehicle (Train, Tram, Autonomous, Heavy Vehicle, Mining Vehicle, Fleet, Fishery): The automotive industry employs these computers in managing vehicle telematics, fleet management systems, collision detection, and autonomous navigation systems. These computers must withstand vibration, high temperatures and comply with railway application or road vehicle standards.

- Manufacturing (Robot, Automated Production Line): In the field of manufacturing, fanless industrial computers control robotic arms, CNC machines, and automated production lines. They must adhere to specific safety and reliability standards and be capable of real-time control and machine vision processing.

- Retailing: Retailing applications use fanless computers in POS systems, kiosks, and ATMs. These computers require high reliability, low noise, and a compact design. They must support secure transactions and comply with standards for data security or accessibility.

What are the Advantages of Fanless Computers?

- Industrial fanless computers are reliable and durable. It minimizes mechanical failures and enhances longevity by using passive cooling and special design.

- Their compact size allows for seamless integration into restrictive spaces in industrial setups. Due to the elimination of bulky cooling systems, fanless computers can be condensed into small, space-efficient units without sacrificing performance.

- To withstand constantly moving, shaking, and vibrating environments, such as those in vehicles, industrial fanless computers comply with MIL-STD-810G and other shock and vibration standards. These standards ensure the systems are resilient to physical stressors and facilitate uninterrupted operation even under severe conditions.

- Industrial fanless computers support a broad spectrum of power inputs while accommodating varying power supply voltages in different vehicles. It ensures stable operation and extends the computer’s lifespan by protecting it from potential damage due to power fluctuations or improper voltage levels.

Introducing SINTORNES’ Fanless Industrial PC Series

SINTRONES presents a series of fanless industrial PCs that are rugged, compact, and fanless, specially designed to withstand harsh environments. These devices are constructed with robust materials that provide dust protection, ensuring their ability to perform under extreme weather conditions without internal component damage. Our products and solutions feature high-speed performance and adaptable expansion slots, making them highly suitable for demanding industrial applications such as railway control systems, outdoor monitoring, and large-scale processes like train signaling and control.

Our fanless industrial PCs have been certified by ISO 9001, IRIS ISO/TS 22163, and EN 50155, and are remotely and easily managed. We invite you to explore the resilience and versatility of SINTRONES industrial computers, which are ideal for today’s challenging industrial environments.